Bargraph displays are ideal if you want to know the ‘fullness’ of a tank, ‘hotness’ of a process etc. Use them in applications where you want to be able to know, at a glance, the relative value of a variable. Similar in principle to moving pointer displays, yet more reliable and robust because they have no moving parts.

Choose from 2 models:

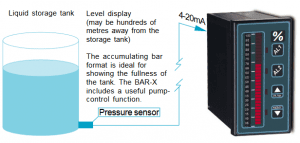

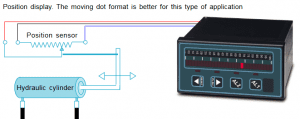

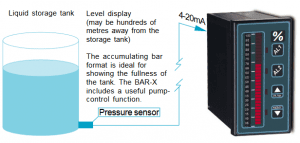

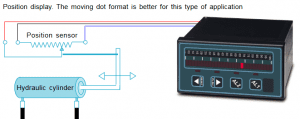

These displays can be set with a moving dot or accumulating bar format, to suit such applications as position monitoring or tank level indication. And, you can mount the display horizontally or vertically to suit different applications. For example …

To scale and identify the readout, we offer to print customised scale labels for you, free of charge.

The Alarms on the BAR-X model have Failsafe (de-energise on trip) changeover relay outputs, with an LED to show relay status. The alarms are supplied as HI-LO format, but you can easily set HI-HI or LO-LO.

There is also a ‘pump-control’ mode available as standard, where the low alarm will latch, and will only reset when the input exceeds the high alarm limit.

| Input Signal | 4-20mA, 0-20mA, 0-10mA, -5 to +5V, 0-10V, 1-5V |

|---|---|

| Alarm Outputs | None (0), 2 x SPCO mechanical relays (SPCO) |

| Excitation | 24V DC @ 30mA |

| Displayed Reading | 30 segments |

| Orientation | Horizontal (H), Vertical (V) |

| Scale length | 75mm |

| Supply Voltage | 95-265V AC (AC), 11-30V DC (DC) |

| Power Consumption | 3 VA |

| Segment Colour | Green, Red |

| Bezel Size | 96mm wide x 48mm high |

| Panel Cutout | 92mm wide x 45mm high |

| Depth Behind Panel | 125mm |

| Front Panel Sealing | IP54 standard, IP67 with optional SPC4 cover |

| Operating Temperature | 0C to +50 Deg. C |

| Storage Temperature | -40 to +85 Deg.C |

| Case Material | 94V-1, UL Rated Noryl |

We know you’re excited to receive your order, and we’re working hard to keep parcels moving as quickly as possible whilst also ensuring the safety of our factory and warehouse staff.

Please note, that delivery times are confirmed at the time of order and are estimated, not guaranteed. If you would like to check on the availability and lead time of a particular product, please contact Customer Services at [email protected].

No matter where you are, the size of your order, or how fast you need it – we have a delivery option for you!

For current delivery prices please click on the link below. For items not listed in the price list, please request a quote and we will endeavour to provide a price for you as quickly as possible.

https://www.london-electronics.com/pricelists/delivery-within-mainland-uk/

The method of shipment will be at our discretion unless otherwise specified on our acknowledgment. We will however take all reasonable steps to comply with your specific shipping requests

At this time we do not accept international payments through our shop. However, no matter where you are in the world we can supply our products to you. Please request a quote through the online form, and a member of our sales team will be in contact with you to discuss further.

Price depends on the delivery location, weight, and value of your order.

You are more than welcome to use your own courier to collect your order if preferred. Alternatively, you can come and see us to collect the order in person.

For either of these options simply select ‘Collect in Person’ or ‘Collect via own Courier’ at the checkout.

It’s safe to say that we’re living through some changeable times right now, so if you’d like to stay up to date with the latest news on how we’re responding, sign up to our newsletter on the link below.

Bargraph displays are ideal if you want to know the ‘fullness’ of a tank, ‘hotness’ of a process etc. Use them in applications where you want to be able to know, at a glance, the relative value of a variable. Similar in principle to moving pointer displays, yet more reliable and robust because they have no moving parts.

Choose from 2 models:

These displays can be set with a moving dot or accumulating bar format, to suit such applications as position monitoring or tank level indication. And, you can mount the display horizontally or vertically to suit different applications. For example …

To scale and identify the readout, we offer to print customised scale labels for you, free of charge.

The Alarms on the BAR-X model have Failsafe (de-energise on trip) changeover relay outputs, with an LED to show relay status. The alarms are supplied as HI-LO format, but you can easily set HI-HI or LO-LO.

There is also a ‘pump-control’ mode available as standard, where the low alarm will latch, and will only reset when the input exceeds the high alarm limit.

| Input Signal | 4-20mA, 0-20mA, 0-10mA, -5 to +5V, 0-10V, 1-5V |

|---|---|

| Alarm Outputs | None (0), 2 x SPCO mechanical relays (SPCO) |

| Excitation | 24V DC @ 30mA |

| Displayed Reading | 30 segments |

| Orientation | Horizontal (H), Vertical (V) |

| Scale length | 75mm |

| Supply Voltage | 95-265V AC (AC), 11-30V DC (DC) |

| Power Consumption | 3 VA |

| Segment Colour | Green, Red |

| Bezel Size | 96mm wide x 48mm high |

| Panel Cutout | 92mm wide x 45mm high |

| Depth Behind Panel | 125mm |

| Front Panel Sealing | IP54 standard, IP67 with optional SPC4 cover |

| Operating Temperature | 0C to +50 Deg. C |

| Storage Temperature | -40 to +85 Deg.C |

| Case Material | 94V-1, UL Rated Noryl |