Factory KPI displays and Production Line Monitoring

In a competitive market, you need to respond immediately to anything which could affect your production line efficiency. To be able to do this a monitoring system is required to help you identify and locate the problem. The system can also indicate current conditions to employees, which helps to maintain their safety.

That is exactly what we specialise in. Since 1992 we have helped some of the world’s best-known manufacturers deliver the ultimate in their production line efficiency.

OEE and KPI Displays for boosting factory performance

Tell us what is important in your process and we will develop an affordable, reliable and effective production line KPI monitoring system for you.

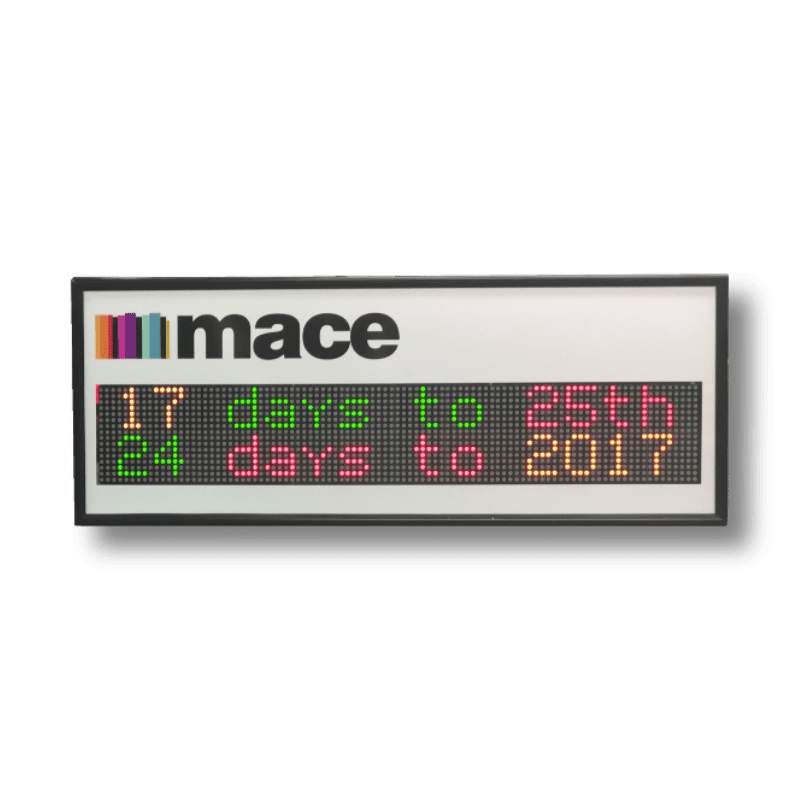

Our displays provide a clear, visual method of monitoring your factory performance. They can accept most common input signals which enable them to work with most production line sensors. Once an input has been received you can decide how you would like this information conveyed. Our TITAN displays show alphanumeric messages using tri-colour LEDs, which allow messages to be colour coded. Alternatively our FUSION displays show numeric messages. They can be fitted with alarms or beacons which can indicate production line status.

Our displays are designed to meet your specific requirements. Our digit heights range from 57mm to 200mm which allow a viewing distance from 25m to 200m. Commonly our displays are made of uPVC and sealed to IP65 but we can also produce displays in stainless steel enclosures which are sealed to IP66. They come with a 3 year warranty and full remote support.

“Hi Bob,

Here are some photos of the Displays and a short video in action.

Thanks for some good work by LEL, they are just what we wanted.”

Best Regards,

Denis Sturman

C&I Engineer

Saint Gobain Glass

Production Display examples

“We had a specific requirement for our station timers and London Electronics were not fazed by this at all.

James visited our site with demo models and explained very clearly what he needed from us in order to get the best product.

We had changing circumstances in our project and LE responded quickly to all. When faced with meeting a much earlier deadline than expected they really pushed on so we could get all the timers we needed.

Overall they are a very professional company, the products they have supplied are top quality and I will be using them in any further projects.”

Paul Johnson, Maintenance Engineer: Bentley Motors Limited

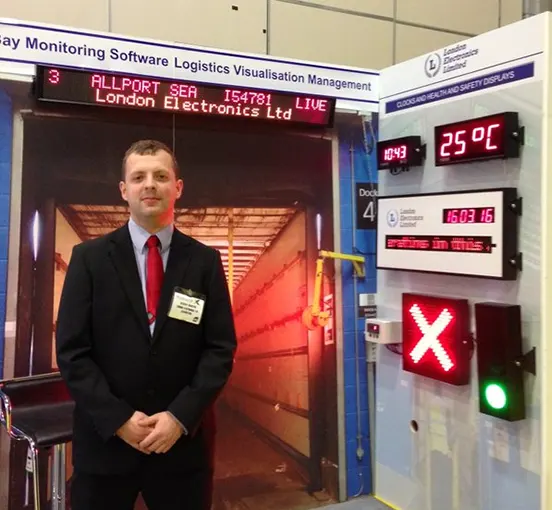

A wide range of warehousing monitoring and display systems, such as routing signs, bay status displays, clocks, temperature and humidity displays etc.

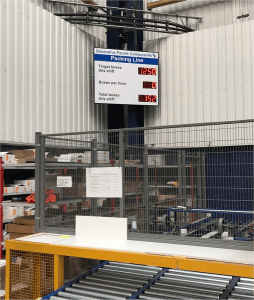

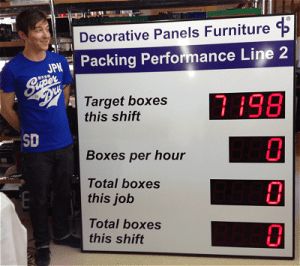

Flat pack furniture production monitoring – a case study

The task

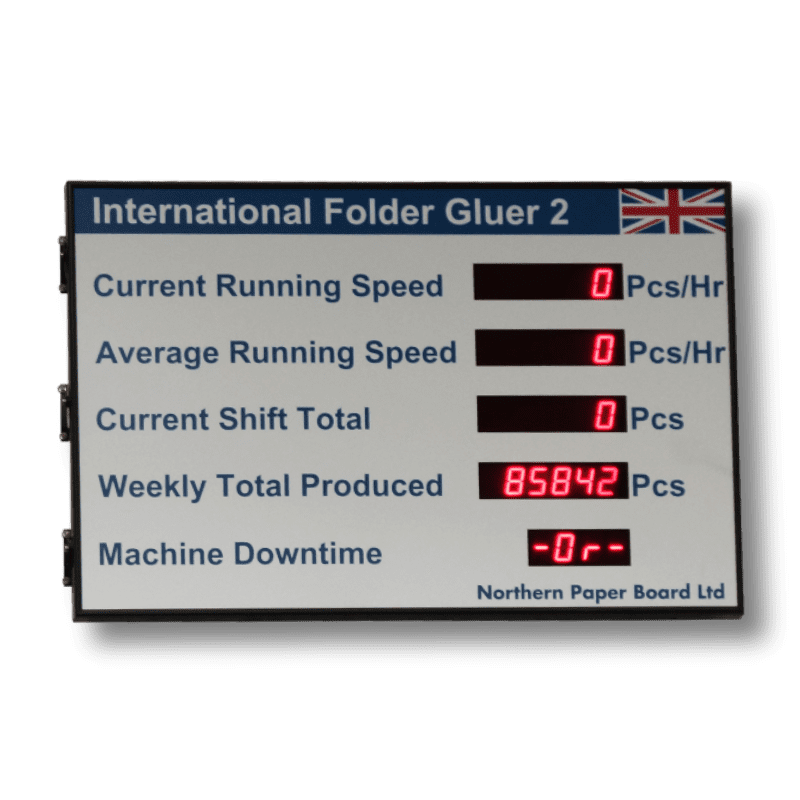

Decorative Panels Furniture asked us to design and build production monitoring displays for each of their flat-pack component production lines.

They wanted a system which was easy to install and use. It also needed to be able to withstand the dusty conditions created by the wood saws.

The information needed to be updated live, so they could see at a glance how they were performing, and take any action necessary to ensure they met their targets.

The production lines are up to 60m long, so they needed displays which would be easy to see from that distance.

Our solution

We designed a fully sealed enclosure to accept 4 of our Fusion large display modules. Each module can accept pulses directly from proximity sensors, and can count pulses, compute rate, compute average speed etc.

We used our standard 6 inch high digits to give the necessary clear viewing up to 60m.

We styled the front of the displays to match the logo and colour scheme used by Decorative Panels. This reinforces their corporate branding impact when inviting prospective customers to view their facility.

This display system is a fully self-contained display which accepts pulses from the line and computes real-time key performance data.

This display system is a fully self-contained display which accepts pulses from the line and computes real-time key performance data …

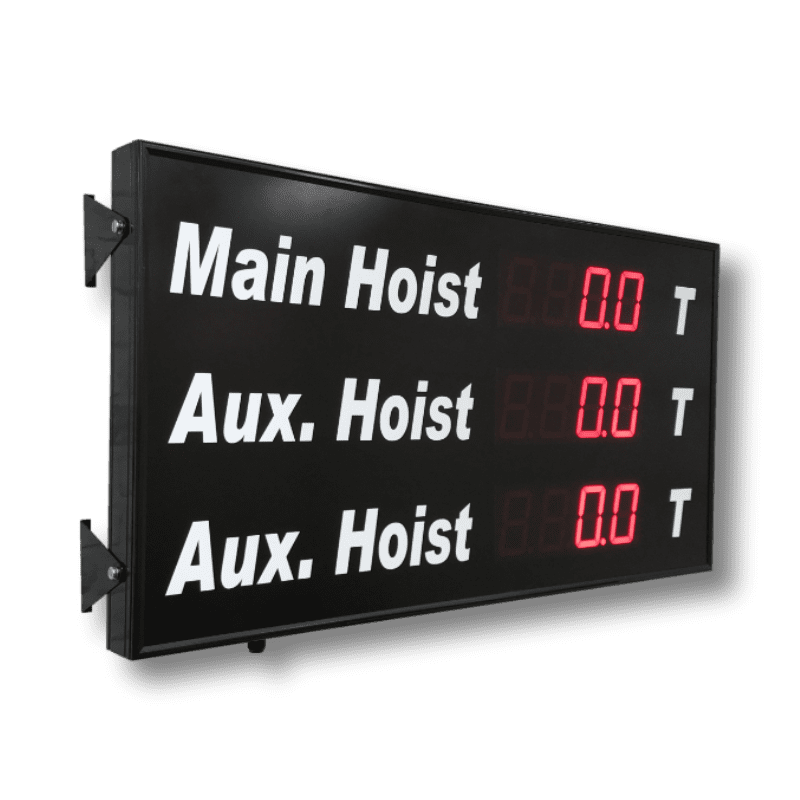

This display gives an easily visible live display of crane tonnage.

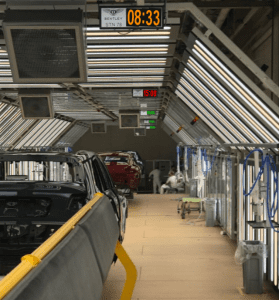

Production line efficiency large digital display with clock

A combined synchronised clock and individual production output counter for each componentmanufacturing station.

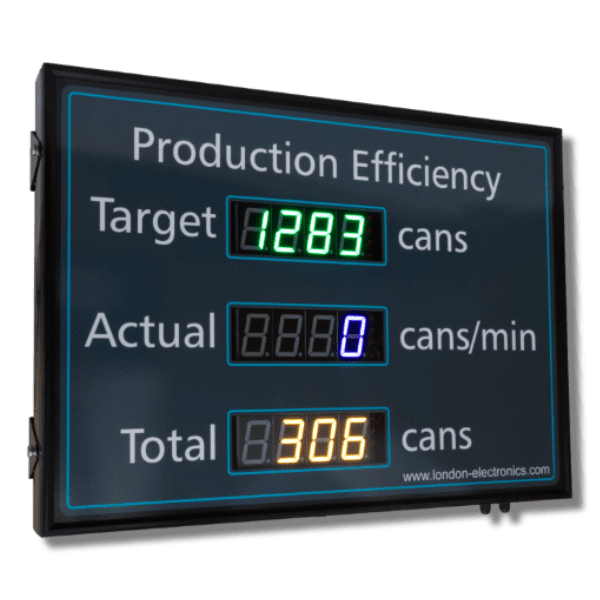

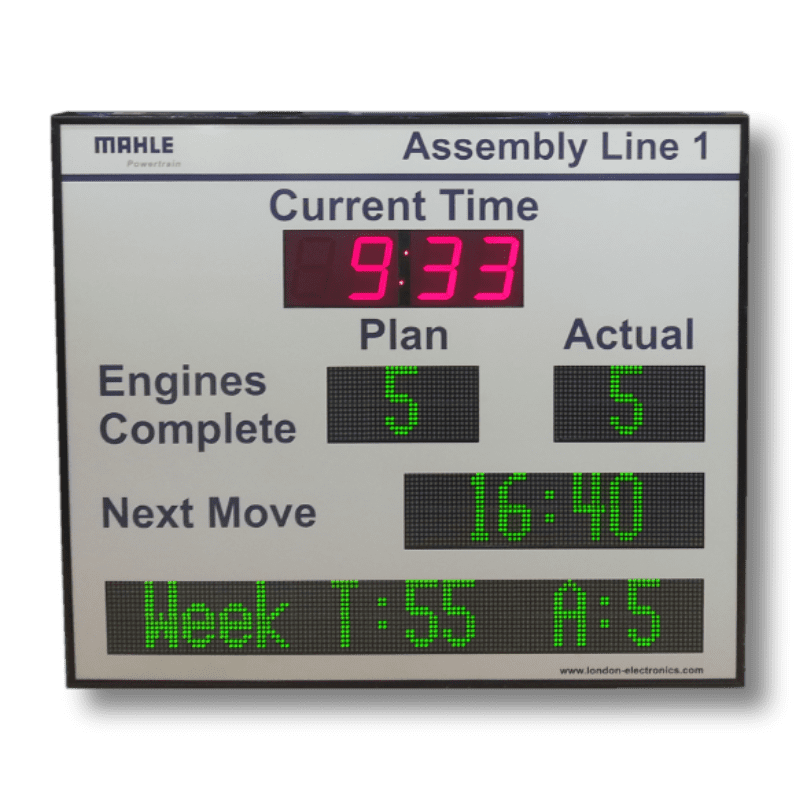

High performance engine production line efficiency display

An engine production line efficiency display.