M & J Seafoods

Improving Efficiency in a Challenging Production Environment

Client Background

M&J Seafoods, based in Fleetwood and now part of the Brakes Group, is one of the UK’s leading suppliers of fresh and frozen seafood. The company operates in a fast-paced, highly demanding production environment where product freshness, hygiene, and efficiency are critical.

The Challenge

M&J Seafoods faced a difficult sensing and monitoring problem on their filleting line. The environment was extremely wet and humid, making it challenging to detect fish fillets reliably using conventional sensors. At the same time, management needed a clear and simple way to:

-

Monitor production targets versus actual throughput in real time.

-

Improve line efficiencies by quickly identifying shortfalls.

-

Communicate live performance data to both supervisors and shop floor staff.

Traditional monitoring methods were not robust enough to cope with the wet conditions and did not provide the transparency needed to engage the workforce effectively.

The Solution

London Electronics designed and installed a tailored monitoring and display system, built to thrive in harsh production environments. Key elements of the solution included:

-

IP67-rated sensors: Durable and water-resistant sensors capable of accurately detecting fish fillets despite the wet processing area.

-

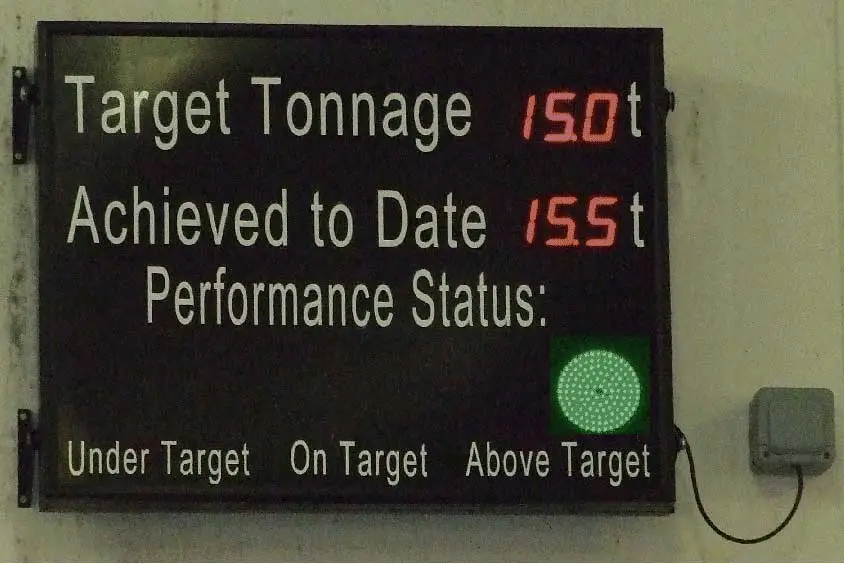

Large digital production displays: Two wall-mounted, high-visibility LED displays showing live production counts and targets, ensuring workers could instantly see progress against goals.

-

Andon light integration: Visual alerts to quickly highlight line issues and help supervisors intervene promptly.

-

Remote viewing software: A locally hosted platform allowing live production data to be distributed across the factory. This fed smaller LCD screens positioned in different areas, ensuring visibility at every level of the workforce.

The Results

The new system delivered measurable improvements across multiple areas:

-

Enhanced visibility of performance: Operators and supervisors could see in real time how the line was performing, creating a culture of accountability and teamwork.

-

Increased efficiency: Early detection of shortfalls or stoppages reduced downtime and improved throughput.

-

Stronger workforce engagement: By making targets transparent and visible to everyone, staff became more invested in meeting goals.

-

Reliable operation in harsh conditions: The IP67-rated equipment ensured long-term durability, even in one of the toughest production environments.

Conclusion

By combining robust sensor technology with clear, accessible production displays, London Electronics helped M&J Seafoods overcome a unique monitoring challenge. The solution not only improved line efficiency but also fostered better communication and engagement across the factory floor — proving the value of well-designed display systems in even the harshest of environments.